Superalloy manufactures hundreds of complex precision machined parts and components many different markets and segments. Embracing the diversity of each market enables Superalloy to utilize a wide range of materials and processes. Along with our premier Electro-Chemical Machining process, we also offer the following machining capabilities:

■ Deep hole broaching up to 20 feet

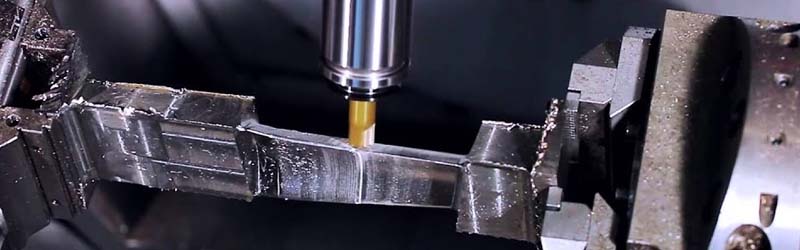

■ Multi-axis high speed milling

■ Turning

■ Grinding

■ CMM inspection

■ Horizontal and vertical balance

■ Module assembly

■ Hybrid machining capabilities

We have a wide range of machining capabilities to tackle the most demanding projects.

With our Electro Chemical Machining and more traditional machining methods, we offer a unique advantage.

We have worked with a range of customers, including GE Aviation, Siemens, Rolls-Royce, Aerojet Rocketdyne and more.

We design and manufacture blisks / IBR, blades, vanes, cases and structures across a wide variety of markets.

Superalloy's capabilities expand across three different plants, with a total of more than 175,000 sq ft of manufacturing space.

Superalloy Manufacturing Solutions Corporation has worked in varied markets with customers over the past 40+ years, including GE Aviation, Siemens, Rolls-Royce, Aerojet Rocketdyne, UTC Aerospace and many more. We are confident that we can help you with our expertise and diligence. Find out what we can do for you.

Contact Us to Get Started